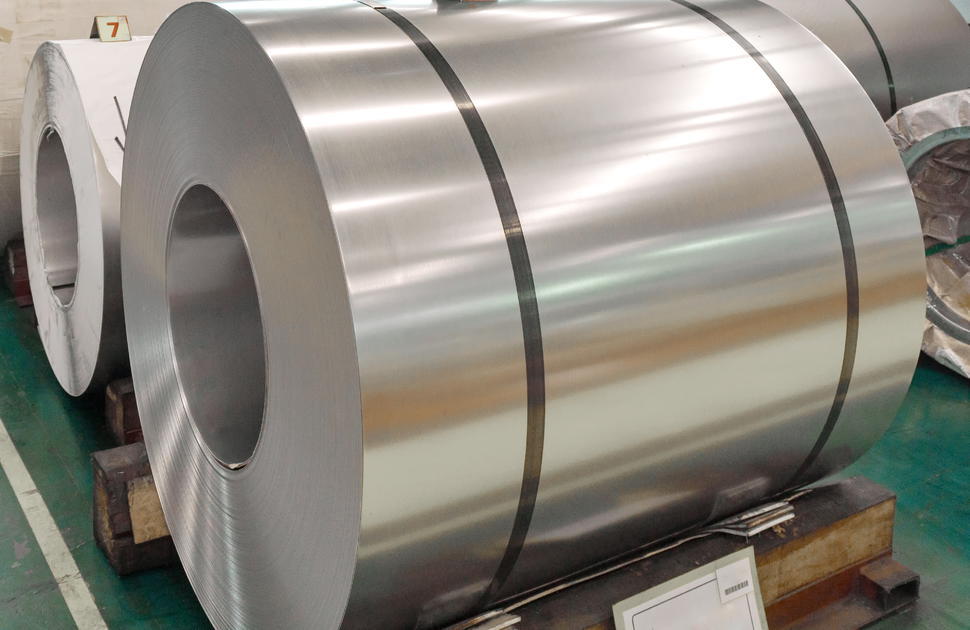

Stainless Steel- What is it, and what are the benefits?

The many unique values provided by stainless steel make it a powerful candidate in materials selection. Engineers, specifiers, and designers often underestimate or overlook these values because of what is viewed as the higher initial cost of stainless steel. However, over the total life of a project, stainless is often the best value option

Stainless steel is essentially a low-carbon steel which contains chromium at 10% or more by weight. It is this addition of chromium that gives the steel its unique stainless, corrosion-resisting properties.

The chromium content of the steel allows the formation of a rough, adherent, invisible, corrosion-resisting chromium oxide film on the steel surface. If damaged mechanically or chemically, this film is self-healing, providing that oxygen, even in very small amounts, is present. The corrosion resistance and other useful properties of the steel are enhanced by increased chromium content and the addition of other elements such as molybdenum, nickel, and nitrogen.

Benefits of Stainless Steel

CORROSION RESISTANCE

Lower alloyed grades resist corrosion in atmospheric and pure water environments, while high-alloyed grades can resist corrosion in most acids, alkaline solutions, and chlorine-bearing environments, properties which are utilized in process plants.

FIRE AND HEAT RESISTANCE

Special high chromium and nickel-alloyed grades resist scaling and retain strength at high temperatures.

HYGIENE

The easy cleaning ability of stainless makes it the first choice for strict hygiene conditions, such as hospitals, kitchens, abattoirs, and other food processing plants.

STRENGTH-TO-WEIGHT ADVANTAGE

The work-hardening property of austenitic grades, which results in a significant strengthening of the material from cold-working alone, and the high strength duplex grades, allow reduced material thickness over conventional grades, therefore cost savings.